Helical Tiebacks

Products / Helical Tiebacks

product

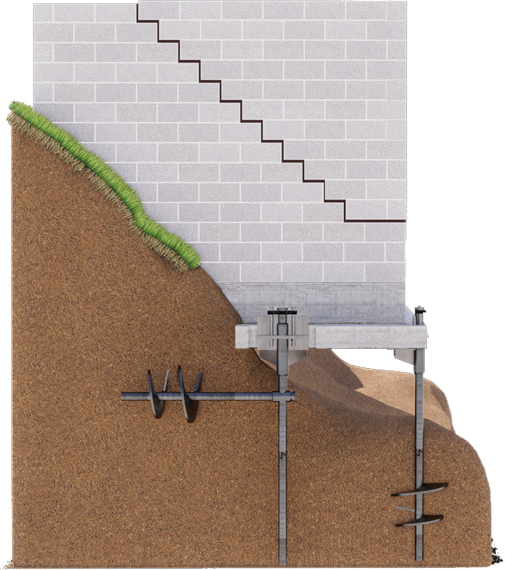

Helical Tiebacks

Helical tiebacks utilize proven engineering methods to secure and provide tension resistance for retaining walls, guy wires for power poles and towers, and slope retention. They can be combined with push piers or helical piles to provide combined tension and compression design capacities. Because of this, tiebacks are a very versatile product.

- Predictable capacity

- No excavation required on the high-grade side of foundation or retaining walls.

- Installs with either handheld or small equipment in areas of limited or tight access

- Load test can be conducted immediately after installation

- Generates no spoils

- Clean installation ‘ no messy grout

- All-weather installation

Features of Helical Tiebacks

- Lead sections available in 2, 5 and 7-foot lengths

- Extensions available in 3, 5 and 7-foot lengths

- Socket and bolt connections

- Helical leads and extensions available with helix blade configurations to meet project-specific requirements.

- Helix blade diameters of 8, 10, 12 and 14 inches.

- Available with hot-dipped galvanized coating for added corrosion resistance.

All of these benefits make this an easy, cost-effective solution for your property. With the wide variety of applications, this option suits residential, commercial, and even industrial situations where the speed of installation, budget-friendly options, and durability are all serious factors in choosing a foundation product.

- 1.5 inches round corner square shaft (C1530 Modified)

- Torque Strength Rating = 7,000 ft.-lb.

- Torque Correlation Factor (Kt) = 10 ft-1

- Connecting Bolts: 0.75-inch diameter Heavy Hex Machine Bolt (SAE J429 ‘ Grade 8)

- Ultimate axial capacity based upon installation torque = 70 kips (tension)

- Allowable axial capacity based upon installation torque = 35 kips (FOS = 2)

- Allowable axial capacity based upon shear of coupling bolt = 26.5 kips (per Allowable Stress Design Method)