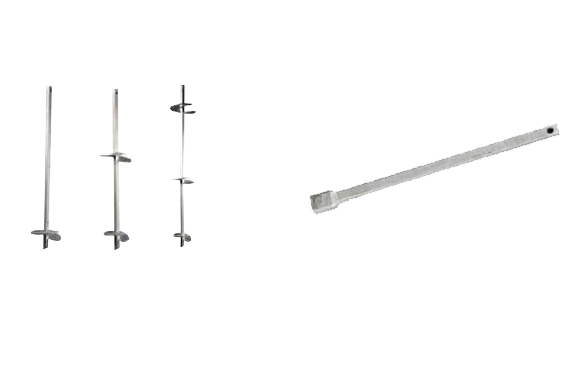

SQUARE SHAFT HELICAL PILES

Square shaft helical piles or piers are used in applications where tension is the primary focus. The innovative design provides greater tensile strength and torque capacity while retaining the ease of installation. As an additional bonus, they create minimal soil disruption, making them a practical and attractive method of repair.

At Grip-Tite Manufacturing, we’ve been setting the industry standard for nearly 100 years. While our company has grown significantly since our founding, our commitment to providing high-quality foundation repair products has remained the same. When you choose helical piers from Grip-Tite, you can do so confidently knowing you’re getting products crafted by industry pioneers. Call our team today!

Benefits of Square Shaft Helical Pile Systems from Grip-Tite Manufacturing

As previously mentioned, if tension is the primary focus, square shaft helical piers are the ideal helical pier option. In conjunction with our strong helical tiebacks, our square shaft helical piers are an effective method for correcting and straightening walls. Square shaft helical piers offer a number of benefits, including:

- Higher Yield and Tensile Strength

- Higher Torque Capacity

- Efficient, Quick Installation

- Minimal Soil Disruption

- Not Adversely Affected by a High Water Table

- Can be Installed Anytime

Check out the specs below to get a good idea of the product as well as its advantages and benefits, then give us a call today to get started on your order!

60 KIPS Ulitmate Capacity From Torque

PRODUCT INFORMATION

GTRDS150 Series Square Shaft Heliecal Piples/Tiebacks| Catalog | ||

|---|---|---|

| Number | Description | WT. |

| GTSQS150-2LS8 | 2′ LEAD W/ 8″ | 14 |

| GTSQS150-2LS10 | 2′ LEAD W/ 10″ | 16 |

| GTSQS150-2LS12 | 2′ LEAD W/ 12″ | 21 |

| GTSQS150-5LS8 | 5′ LEAD W/ 8″ | 45 |

| GTSQS150-5LS10 | 5′ LEAD W/ 10″ | 47 |

| GTSQS150-5LS12 | 5′ LEAD W/ 12″ | 50 |

| GTSQS150-5LS810 | 5′ LEAD W/ 8″-10″ | 52 |

| GTSQS150-5LS1012 | 5′ LEAD W/ 10″-12″ | 58 |

| GTSQS150-7LS10 | 7′ LEAD W/ 8″ | 61 |

| GTSQS150-7LS12 | 7′ LEAD W/ 10″ | 66 |

| GTSQS150-7LS810 | 7′ LEAD W/ 8″-10″ | 67 |

| GTSQS150-7LS1012 | 7′ LEAD W/ 10″-12″ | 74 |

| GTSQS150-7LS81012 | 7′ LEAD W/ 8″-10″-12″ | 79 |

| GTSQS150-3EA | 3′ EXTENSION | 25 |

| GTSQS150-5EA | 5′ EXTENSION | 40 |

| GTSQS150-7EA | 7′ EXTENSION | 55 |

| GTSQS150-COUPLER | 3′ EXTENSION COUPLER | 3 |

| HELIX DIAMETER (in) | NET AREA (ft squared) |

|---|---|

| 8 | .30 |

| 10 | .50 |

| 12 | .75 |

| 14 | 1.0 |

-

- Shaft (AISI 1060): RCS 1.50″ x 1.50″ F, = 85 ksi min; F, = 120 ksi min.

- Cross section area A2.12 in squared

- Moment of interia, I: 0.39in 4 squared

- Sectional Modulus, S: 0.41 in 3 squared

- Radius of Gyration, r: 0.42in

- Coupler (A151 1060): UPFORGED 2.5″ x 2.5″ x 0.45″ wall

- Bolts (ASTM 490) Grade 8: 1-3/4 diam. x 3.5″ SSae J429

- Helices (ASTM A36): Thickness – 0375″;8″.10″.12″.14″ Diam.

- Coating: Hot-Dip Galvanization to ASTM A123 Optional

- Ultimate Capacity – Torque Ratio, K: 10ft 4 squared

- Recommended Torsional Strength, T: 6,000 ft-lbs

- Ultimate Mechanical Compression Capacity: 120 kips

- Allowable Mechanical Compression Capacity: 60 kips

- Ultimate Capacity – Compression: 60 kips

- Allowable Capacity – Compression and tension: 30 kips

- Allowable Shear Capacity: 30 kips

SPECIFICATIONS

- Lead sections and extensions can be configured to achieve design depth and capacity.

- Lead sections available in 2, 5, and 7-foot lengths.

- Extensions are available in 3, 5, and 7-foot lengths.

- Helical piers available with single, double, and triple helix lead sections.

- Helix blade diameters of 8, 10, 12, and 14 inches.

- Available with hot-dipped galvanized coating for added corrosion resistance.

- Lead sections of pier can be configured to achieve design depths and capacities.

- Minimal excavation required around foundation area..

- Installs quickly with lightweight or portable equipment.

- Vibration-free installation.

- No wait-piers installed in any or all weather.

- Installs in areas with limited or tight access (without generating spoils).

- Pier system installed below grade – not visible once installation is complete.

- Cost-effective (gets a structure back on solid ground).

- Permanent solutions – prevents further vertical movement.

- All-weather installation

- Can be installed with either portable or small equipment.

- Can be installed in areas of limited or tight access.

- Foundation concrete can be poured immediately following installation.

- Lead sections can be configured to achieve design depth and capacity.

- Cost-competitive versus other deep foundation alternatives.

- Vibration-free installation.

- Installs quickly without generating spoils.