PUSH PIER SYSTEM

What Is A Push Pier System Used For?

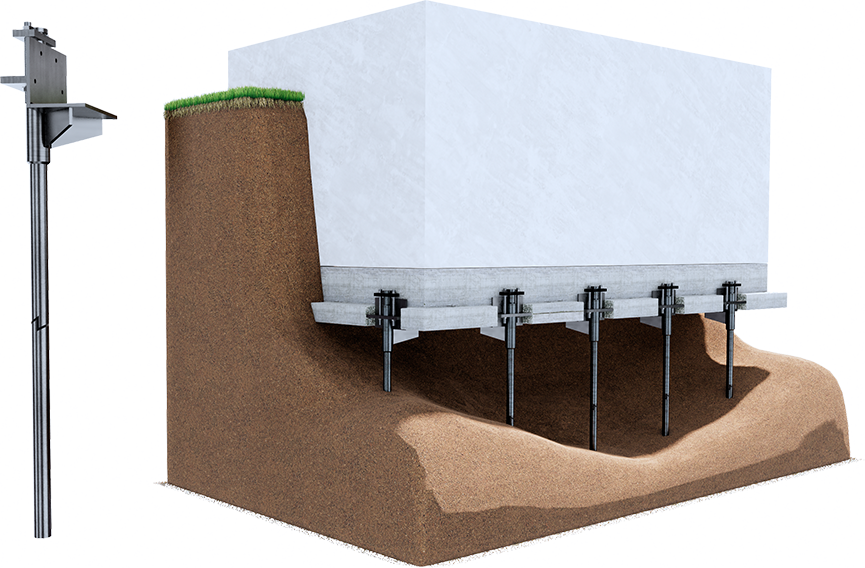

Introducing the Grip-Tite Foundation Push Pier – an advanced solution tailored to address foundation settlement with unparalleled precision. Engineered to restore stability to failing foundations, our push pier system employs robust steel tubes strategically designed to leverage the weight of the structure itself. This innovative approach utilizes hydraulic force to drive the piers down to bedrock or other reliable load-bearing strata, providing a steadfast foundation stabilization and correction mechanism.

The key to the Grip-Tite push pier system lies in its adaptability and effectiveness across a spectrum of foundation settlement issues. Whether your structure is experiencing subtle shifts or significant settling, our push pier technology is designed to accommodate various degrees of foundation distress. As the steel tubes penetrate the soil, they not only stabilize the foundation but also offer the potential for correction, mitigating the adverse effects of settlement.

Grip-Tite’s commitment to quality ensures that our system is manufactured to the highest industry standards. The materials used in the construction of our push piers are durable and reliable, providing long-lasting support for structures of all sizes. Additionally, our system is versatile enough to complement other foundation repair methods, offering a comprehensive solution tailored to the specific needs of each project.

When you choose the Grip-Tite Foundation Push Pier, you are choosing a proven and trusted solution backed by years of engineering expertise. Experience the difference that precision, innovation, and reliability can make in foundation repair. Contact us today to explore how Grip-Tite can elevate your approach to foundation settlement challenges, providing enduring stability and peace of mind for your structures.

Push Pier System

Our Push Pier tube are manufactured from high strength/low alloy hot rolled steel. Push Pier structural tubes are offered in 3″ diameter. Grip-Tite offers these tubes in two thicknesses; our Standard Duty is 0.12″ and our Heavy Duty is 0.188″

- An end-bearing pier that does not rely on friction for capacity

- Each pier load tested during installation

- Ability to reach greater depths using a starter tube with friction collar

- High-strength steel pier sections and sleeved couplings have high resistance to bending

- Long life span, resistance to corrosion (design life in moderate soils more than 100 years)

- Available with hot-dipped galvanized coating for added corrosion resistance

SPECIFICATIONS

- 3.0-inch Outside Diameter (O.D.) x 0.120-inch wall tube steel, ultimate tensile strength = 80,000 psi (min.), yield tensile strength = 70,000 psi (min.)

- 2.75-inch O.D. x 0.120-inch wall tube steel, ultimate tensile strength = 80,000 psi (min.), yield tensile strength = 70,000 psi (min.)

-

-

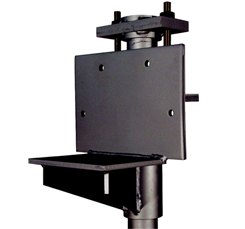

- <strong>Bracket Tube

3.875-inch O.D. x 3.125-inch Inside Diameter (I.D.) x 10-inch long DOM mechanical steel tubing conforming to ASTM 513 ‘ Type 5 / Grade 1026. Ultimate tensile strength = 100,000 psi (min.), yield tensile strength = 90,000 psi (min.) - Angle Bracket

0.5-inch thick flat plate conforming to ASTM A-36 hot rolled steel bent to form a 90-degree angle with equal sides of approximately 8 inches. Ultimate tensile strength = 58,000 psi (min.), yield tensile strength = 36,000 psi (min.)

- <strong>Bracket Tube

-

- Bra

-

-

- cket Support Strap</strong>

- 0.375-inch thick

- x 3 inches wide x 21.25 inches flat bar conforming to ASTM A-36 hot rolled steel which is bent into a “horseshoe” shape around the bracket tube. Ultimate tensile strength = 58,000 psi (min.), yield tensile st

rength = 36,000

- psi (min.)

-

- Top

- >

- Plate</strong>

-

- 0.75-inch thick x 5.5 inches wide x 9.5 inches long conforming to ASTM A-36 hot rolled steel. Ultimate tensile strength = 58,000 psi (min.), yield tensile strength = 36,000 ps

i (min.)

- <st

-

- rong>Cap Plate

- 1.0-inch thick x 4.0 inches wide x 8.5 inches long conforming to ASTM A-36 hot rolled steel. Ultimate tensile strength = 58,000 psi (min.), yield tensile strength = 36,000 psi (min.)

- Weld

E71T1, minimum tensile strength = 71,000 psi ‘ performed by AWS certified welder - Threaded Rod</strong>

0.75-inch diameter x 12 inches long ASTM A311 ‘ Class B / Grade 8 Zinc Plated. Ultimate tensile strength = 150,000 psi, yield tensile strength = 130,000 psi

- Foundation Pier System, which includes pier tube, tube reinforcing insert and foundation bracket, tested by an Independent Laboratory to peak loads exceeding 70,000 pounds (70 kips).

See ICC-ES Legacy Report #22-03 prepared by the International Code Council