HELICAL TIEBACK ANCHORS

Helical tieback anchors are used to repair foundation damage and fix potential shifting/settling. If you are a homeowner, you might be wondering which foundation repair method is best for your home. If you’re a foundation repair company, you might be wondering what kind of products we offer for this kind of repair. Lucky for you, we have both. Grip-Tite is the leading manufacturer of foundation repair and basement waterproofing products in America and has been in business for over 90 years.

For more information on our helical tiebacks and how they can protect your home or take your foundation repair business to the next level, call the team at Grip-Tite today. To find out how you can become a certified Grip-Tite installer, simply fill out our convenient online form.

What Are Helical Tiebacks?

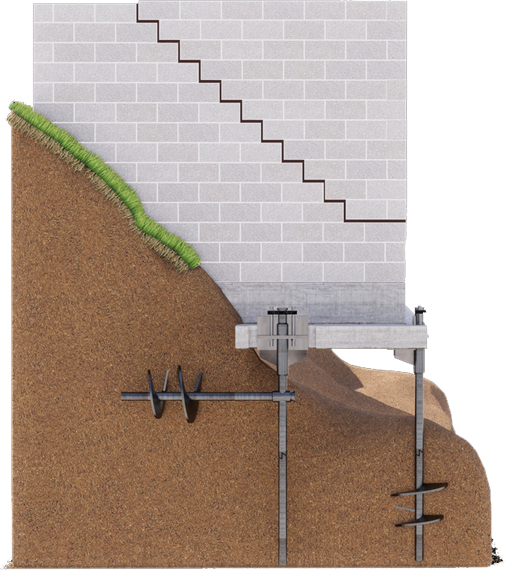

This product is typically used to fix bowing basement walls. They look like large screws and are rotated into the ground facing away from the affected wall. When the tieback is installed correctly in stable soil, it will then pull the bowing wall back into place, supporting it against future shifting/bowing. This option is chosen by many foundation repair experts because it’s a solution proven to last.

What are the Benefits of Helical Tiebacks?

Helical tiebacks utilize proven engineering methods to secure and provide tension resistance for retaining walls, guy wires for power poles and towers, and slope retention. They can be combined with push piers or helical piles to provide combined tension and compression design capacities. Because of this, tiebacks are a very versatile product.

Choose Grip-Tite

Are you ready to experience the best in foundation repair products? Trust Grip-Tite Manufacturing to provide you with top-notch products made for the toughest of repairs. We care about our certified installers and we care about our customers. That’s why we’re available to answer any questions you may have during normal business hours. All you have to do is call today!

If you are a home or business owner looking for foundation repair services you can trust, Grip-Tite has you covered there, too! Simply head over to our “find a certified installer” page to see the list of certified Grip-Tite installers in your area. Choose the one that works best for you, and get the piece-of-mind you deserve knowing that your service is backed by parts that have set the industry standard for more than 90 years. When you want service you can count on, you want Grip-Tite!

- Predictable capacity

- No excavation required on the high-grade side of foundation or retaining walls.

- Installs with either handheld or small equipment in areas of limited or tight access

- Load test can be conducted immediately after installation

- Generates no spoils

- Clean installation ‘ no messy grout

- All-weather installation

- Lead sections available in 2, 5 and 7-foot lengths

- Extensions available in 3, 5 and 7-foot lengths

- Socket and bolt connections

- Helical leads and extensions available with helix blade configurations to meet project-specific requirements.

- Helix blade diameters of 8, 10, 12 and 14 inches.

- Available with hot-dipped galvanized coating for added corrosion resistance.

All of these benefits make this an easy, cost-effective solution for your property. With the wide variety of applications, this option suits residential, commercial, and even industrial situations where the speed of installation, budget-friendly options, and durability are all serious factors in choosing a foundation product.

SPECIFICATIONS

- 1.5 inches round corner square shaft (C1530 Modified)

- Torque Strength Rating = 7,000 ft.-lb.

- Torque Correlation Factor (Kt) = 10 ft-1

- 0.75-inch diameter Heavy Hex Machine Bolt (SAE J429 ‘ Grade 8)

- Ultimate axial capacity based upon installation torque = 70 kips (tension)

- Allowable axial capacity based upon installation torque = 35 kips (FOS = 2)

- Allowable axial capacity based upon shear of coupling bolt = 26.5 kips (per Allowable Stress Design Method)